English

▾

English

▾

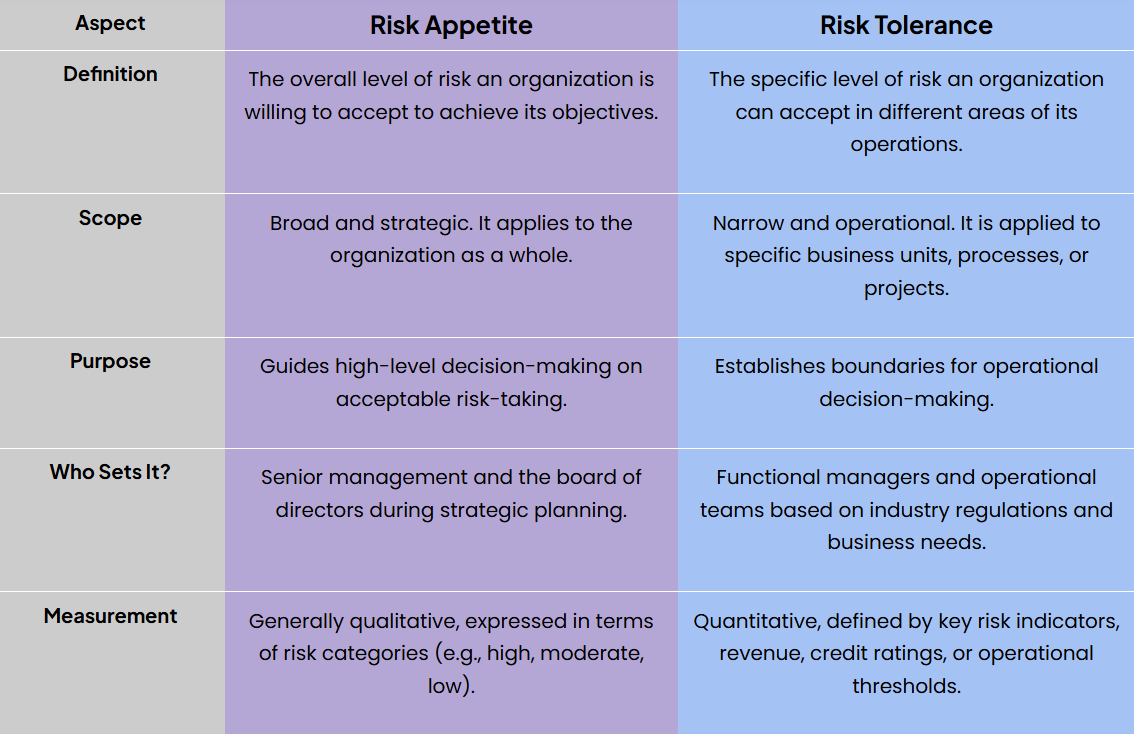

In quality management, making informed decisions about risk is essential to maintaining high standards while balancing operational efficiency and business goals. Risk appetite and risk tolerance are two key concepts that help organizations navigate this balance. While often used interchangeably, they serve distinct roles in guiding how much risk a company is willing to take and how much it can afford to withstand in its quality management processes.

Understanding the difference between these two concepts, how they interact, and how they apply in quality management ensures that organizations take proactive, well-calculated risks that enhance product quality, compliance, and customer satisfaction without exposing the business to unnecessary vulnerabilities.

Basics of Risk Appetite & Risk Tolerance

One of the most valuable aspects of defining risk appetite and tolerance is the conversation itself. The best risk discussions challenge existing perspectives and lead to better decision-making. By clearly defining risk appetite and tolerance, companies can strike the right balance between risk-taking and risk control, ultimately driving long-term success.

Risk appetite defines the level of uncertainty an organization is willing to accept in pursuit of its quality objectives. It is a strategic decision, often set by senior management, that aligns with broader business goals. In quality management, risk appetite determines how much variability in processes or product specifications a company is willing to accept without compromising safety, compliance, or customer trust.

For instance, a pharmaceutical company may have an extremely low risk appetite because product deviations can lead to regulatory penalties and public health risks. On the other hand, a consumer electronics company might have a slightly higher risk appetite, accepting minor product defects as long as they don’t impact functionality or safety.

Risk tolerance, on the other hand, is the specific, measurable level of risk a company can accept in different aspects of quality management. It is operational and tactical, guiding daily decisions through quantifiable limits such as defect rates, product recalls, or customer complaint thresholds.

For example, a food processing company might set a risk tolerance level of no more than 0.5% product contamination in its production line. If contamination exceeds this limit, corrective actions, such as process adjustments or supplier changes, must be implemented. While risk appetite is broad and qualitative, risk tolerance is precise and measurable, ensuring that quality teams have clear guidelines on acceptable risk levels in various operational areas.

Why Risk Appetite & Risk Tolerance Matter in Quality Management

Organizations that fail to define their risk appetite and tolerance in quality management often face issues such as excessive conservatism (leading to inefficiencies and high costs) or reckless risk-taking (resulting in recalls, customer dissatisfaction, and regulatory penalties).

When these concepts are clearly defined, businesses can:

Improve Decision-Making: Quality managers can make informed choices that balance product quality and cost-effectiveness.

Enhance Compliance: Companies can align their operations with industry regulations and standards without unnecessary over-engineering.

Reduce Waste and Rework: Understanding acceptable defect rates can prevent overcorrection and resource wastage.

Protect Brand Reputation: Setting clear limits ensures that quality issues don’t spiral into full-scale crises.

The following are how risk appetite and risk tolerance have industrial applications:

A. Defining Risk Appetite for Quality Standards

Risk appetite in quality management depends on various factors, including industry regulations, stakeholder expectations, and brand positioning. Companies should establish their risk appetite in a way that aligns with their long-term goals.

For example, an automotive manufacturer with a reputation for safety will have a low-risk appetite for defects in airbags and braking systems. In contrast, a fast-fashion retailer might have a moderate risk appetite, accepting minor imperfections in clothing as long as they don’t impact wearability.

B. Establishing Risk Tolerance Limits to Determine Nonconformances

Risk tolerance should be established through measurable indicators that define acceptable performance levels. Some key metrics in quality management include:

- Defect rates: Maximum acceptable percentage of defective products per batch.

- Customer complaints: The threshold for the number of complaints before taking corrective action.

- Compliance deviations: The number of non-conformances allowed before triggering process reviews.

- Production downtime: The maximum amount of unplanned downtime before requiring a root cause analysis.

For instance, a medical device company might set a risk tolerance level of no more than five minor deviations per 10,000 units, ensuring strict adherence to regulatory requirements.

C. Balancing Risk Appetite and Risk Tolerance in Quality Decisions

The key to effective quality management is ensuring that risk tolerance aligns with the overall risk appetite. If an organization has a low risk appetite but sets excessively high tolerance levels, it may end up compromising product quality. Conversely, an organization with a higher risk appetite but restrictive tolerance levels might face inefficiencies due to excessive quality control measures.

Consider a food safety example:

- Risk appetite: A company aims to maintain high food safety standards while optimizing production costs.

- Risk tolerance: The company sets a microbial contamination limit of 1,000 CFU/g for a certain ingredient. If contamination exceeds this level, corrective actions must be taken.

If this risk tolerance is too strict relative to the company’s risk appetite, it could lead to excessive testing costs and ingredient waste. On the other hand, if the tolerance is too lenient, it might result in safety violations and recalls.

D. Adapting Risk Appetite and Tolerance Over Time

Risk levels in quality management are not static. Changes in industry regulations, technology advancements, and consumer expectations can shift what levels of risk are acceptable. Organizations should periodically reassess their risk appetite and tolerance to ensure they remain aligned with business needs and market conditions.

For example, a cosmetics brand that initially allowed a 5% deviation in product color shades might need to lower its tolerance to 2% due to evolving customer expectations for uniformity.

Prioritize Your Risk Appetite & Risk Tolerance Aspects of Your QMS With Smart Food Safe

Understanding and defining risk appetite and risk tolerance in your quality management system (QMS) should be mainstreamed for establishing compliance, optimizing operational efficiency, and ensuring continuous improvement. However, without the right tools, managing these elements effectively can be quite tedious. This is where Smart Food Safe can give you a revamped approach to quality risk management.

With Smart Food Safe, your organization can define and enforce risk appetite and tolerance levels across all quality functions, ensuring that every decision made aligns with your broader quality strategy. The platform enables enterprises to align their risk management practices with their strategic objectives:

⇒ Risk Identification and Assessment: Smart Food Safe’s Smart HACCP systematically identifies potential hazards (biological, chemical, physical) and aligns them with your risk appetite. It performs hazard analysis and Critical Control Points (CCPs) assessments, helping you understand the likelihood and severity of risks.

⇒ Data-Driven Prioritization: Smart Food Safe’s Smart Supplier helps evaluate supplier risks, such as inconsistent raw material quality. Prioritize vetting suppliers with efficient safety records and set tolerance levels for deviations, like delayed deliveries or contamination. Automated supplier tracking reduces risks that could push you beyond your appetite.

⇒ Alignment with Organizational Goals: Smart Food Safe’s Smart Audit streamlines internal and external audits, flagging high-risk areas like supplier non-conformance or equipment failures. Prioritize corrective actions for gaps that exceed your risk tolerance, ensuring compliance with relevant regulatory standards.

⇒ Establish a Risk Aware Workforce: The platform integrates Smart Training to educate staff on critical risk areas, ensuring they stay within defined limits. Ensure employees understand risk priorities through targeted training. Focus on high-risk areas, like hygiene practices, and set tolerance for errors, such as missed sanitation checks. The module tracks completion and effectiveness, aligning staff actions with your QMS risk goals.

⇒ Corrective and Preventive Action System for NC Management: Smart CAPA drives corrective actions for identified risks, like retraining staff after a hygiene lapse, and preventive measures, such as upgrading equipment to avoid future failures, from problem identification to verifying resolution. Root cause analysis tools within CAPA pinpoint why risks exceed tolerance, along with documentation systems to log CAPA outcomes, informing future risk appetite adjustments with automated workflows.

⇒ Regulatory Compliance as a Baseline: Smart Docs is a document compliance management software that assist in ensuring compliance with industry standards. Smart Docs supports by centralizing and updating risk policies, ensuring audit-ready compliance, enabling proactive risk management while maintaining safety and operational goals.

French

French

Spanish

Spanish

Portuguese

Portuguese