English

▾

English

▾

Winemaking is an ancient art, steeped in deep knowledge of how specific conditions can turn grape or fruit juice into the diverse array of wines we cherish today. Through careful experimentation with yeast-driven fermentation, wineries globally have crafted an extensive range of wine styles.

Vintners combine various grape varieties, yeast strains, and additives in precise, monitored processes to produce wines with unique flavors, aromas, colors, and clarity. Quality control is paramount in this process, guided by global, national, and local regulations that dictate permissible production methods, including the use of additives and processing aids, as well as labeling requirements for wine components.

Overview of Wine Production

Wine is a drink produced by fermenting fruit juice using yeast, with specific processing and additives involved. It has been made since ancient times and holds special significance for Greece, both economically and socially. In the 1960s, Greek wineries adopted modern techniques, leading to a diverse range of high-quality wines.

The winemaking process is generally uniform, with variations based on the desired wine type. Here are the steps involved in grape wine production:

- Harvesting: Grapes are picked from the vineyards when they reach the desired level of ripeness.

- Transportation to Winery: The harvested grapes are transported to the winery for processing.

- Crushing and Destemming: Grapes are crushed to release their juice. They are then destemmed to remove the stems from the grape bunches.

- Production of Must: The crushed grapes produce a mixture called must, which consists of juice, skins, seeds, and pulp.

- Juice Separation: For white wines, the juice is typically separated from the skins, seeds, and pulp immediately after crushing. For red wines, the juice, along with the skins, seeds, and pulp, is transferred to fermentation vessels.

- Sulfur Dioxide Treatment: The separated juice must be treated with sulfur dioxide. This treatment helps prevent oxidation and microbial spoilage.

- Fermentation: The treated juice or must is transferred to large fermentation vats. Yeast is added to the vats, initiating fermentation. Over a period of 10 to 30 days, yeast converts sugars present in the juice into ethanol (alcohol) and carbon dioxide.

- Separation from Sediment: After fermentation is complete, the young wine is separated from the sediment (dead yeast cells, grape solids). This process is called racking.

- Clarification: The wine is clarified to remove any suspended particles. This can be achieved through fining agents or filtration.

- Aging: The clarified wine is transferred to oak barrels for aging. Aging can last from several months to several years, depending on the desired style and quality of the wine. Oak aging imparts flavors, aromas, and texture to the wine.

- Blending: Before bottling, wines from different batches or barrels may be blended together. This step helps achieve consistency in flavor and quality.

- Filtration: The wine may undergo filtration to further clarify it and remove any remaining particles.

- Bottling: The finished wine is bottled, sealed, and labeled. It is then ready for distribution and consumption.

A similar process will be followed for any fruit wine production as well. The unique characteristics and quality of wine depend on the grape variety, soil quality, location, climate, and the vinification process, including fermentation. Greek vineyards are located on mountain slopes up to 800 meters above sea level or at sea level. Most vineyards have rocky limestone soil, though a significant portion is on fertile plains. Despite covering vast areas, vineyards use minimal land.

Why Wine Quality Matters

In 2022, the wine market was valued at approximately $346.8 billion, and it is projected to exhibit a compound annual growth rate (CAGR) exceeding 8% from 2022 to 2027. In this scenario, the global wine industry presents fierce competition arising from numerous brands vying for consumer attention. While cost plays a pivotal role, different wine types are priced at ranges below $20 to above $50. This indicates that the success of any wine business hinges on establishing a reputation for delivering exceptional taste and reliability to thrive amidst this competitive landscape.

Winemaking poses many quality and safety hazards such as appearance, taste, consumer acceptability, chemicals, and metal parts. Describing and outlining the incoming hazards for every process stage is essential for quality and safety analysis of winemaking, starting from harvesting the fruits and arriving to distributing the final product.

A wine’s consistency in aroma, flavor, and appearance is crucial for customer loyalty; people return to a particular wine with expectations of a consistent experience from bottle to bottle. Upholding this promise of consistency is the essence of brand integrity. Therefore, investing in technology-driven quality management systems and comprehensive testing strategies is not just a commitment to quality but also an investment in the winery’s brand reputation.

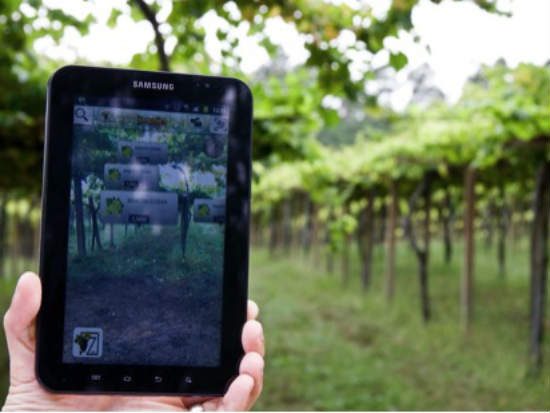

Reference: https://www.greenbiz.com/article/libelium-pours-its-smart-tech-wine-production

Key Determinants for Wine Quality

The quality of wine often stems from a variety of elements, from environmental conditions to cultivation techniques and the intricacies of winemaking. Here are the primary factors that distinguish outstanding wines from the ordinary ones:

Terroir and Climatic Conditions

The concept of terroir, encompassing soil, topography, and climate, profoundly shapes wine quality. Climate and weather patterns play crucial roles in determining grape development, flavor concentration, and the ultimate wine-making potential.

- Climate: While climates tend to be stable over time, they dictate grape characteristics. Cooler climates yield wines with elevated acidity and subtle sweetness, whereas warmer regions foster riper grapes, resulting in richer, sweeter wines with higher alcohol content. Mismatching grape varieties with unsuitable climates can compromise wine quality.

- Weather: Unlike climate, which is more predictable, weather fluctuations can swiftly impact wine quality. Ideal vintages depend on grapes receiving precise conditions for optimal growth and flavor.

Sunlight Exposure and Temperature

Grapevines require specific temperature ranges, typically between 77 and 90 degrees F (25 to 32°C), for efficient photosynthesis and grape development.

- Temperature: In regions where temperatures hover around 60°F, short-cycle grape varieties thrive, while extended-cycle varieties struggle. Excessive heat can expedite grape ripening, potentially hindering flavor and compound maturation.

Cultivation Techniques

Beyond natural factors, a producer’s vineyard management practices influence wine quality. Techniques such as canopy management and pruning play pivotal roles in grape quality and vine health.

- Canopy Management: Pruning away excess leaves and shoots enhances sunlight exposure, vital for grape maturation.

- Pruning and Harvesting: Strategic pruning controls yields and maintains vine vigor. The timing and method of harvesting are critical; premature or delayed harvests can lead to imbalanced grapes. While mechanical harvesting offers speed, it lacks the precision of manual picking, which ensures only the finest grapes are selected.

Art of Winemaking

The wine production process is paramount in shaping its final quality. Winemakers employ a sequence of steps, including maceration, fermentation, extraction, and aging, ensuring consistency to maximize grape potential.

- Winemaking Inputs: Various elements, such as sulfur dioxide, processing enzymes, and oak barrel aging techniques, significantly influence wine quality. Strategic decisions in oxygen management and aging can make the difference between a premium vintage and a mediocre one.

The approach to wine quality as a designed attribute rather than merely controlled has consequential implications for branding. Preventative measures are to be proposed and critical factors and limits should be determined. Studies represent that the CCPs for wine safety are the stages of grape growing, grape harvesting, fermentation, stabilization, aging, and bottling. The most important factors influencing CCPs and CPs should also be understood and controlled as part of the quality management strategy.

Modern Quality Management Techniques for the Wine Industry

Various quality control and assurance mechanisms help wineries maintain and even elevate the quality of their products while streamlining operations. Drawing insights from both boutique producers and larger industry players, here are some measures to be employed for effective quality management in wine businesses for the times ahead:

Vineyard & Seasonal Analysis

Utilizing advanced vineyard management tools to monitor fruit maturity and phenological data allows for real-time access to historical data, enabling the identification of problem areas and the development of proactive quality assurance strategies for current and future vintages.

Real-Time Data for Strategic Planning

Gathering real-time vineyard data to plan harvest schedules meticulously can pave the way to implementing structured processes on time, along with performing standardized operating procedures (SOPs) to minimize errors, especially during the demanding harvest season when staff may be overworked.

Monitoring Through System Integration

Integrate Brix and temperature readings directly for immediate analysis and troubleshooting. Automate the upload of analytical results from external labs to facilitate timely decision-making.

Digital Record-Keeping Systems

Leverage technology tools, such as record management software, to free up your winemaker’s time for more valuable activities like vineyard management, tasting, and professional development. Digital work orders and mobile data entry streamline record-keeping, reducing the reliance on paper-based systems.

Transparent Labeling Management

Execute clear labeling protocols with pre-printed stickers that include information like lot numbers, barrel details, and recent analytical data. Monitor the Cost of Goods Sold (COGS) rigorously and use historical cost data to inform decision-making and increase profitability.

Compliance & Operational Future-Proofing

Automate compliance reporting to reduce administrative burdens and focus on quality control. Modernize operational processes to ensure your business remains agile and adaptable to evolving industry demands and regulatory standards.

By embracing these quality management approaches, wineries can enhance their operational efficiency, maintain consistent product quality, and prepare for future challenges in the wine industry.

Revolutionize Your Wine Industry’s Quality Management with Smart Food Safe

Smart Food Safe brings a multi-faceted quality management solution into the wine business paradigm for boosting wine quality, equipped with digital and tech-enabled modules to be applied in the different farm-to-bottle procedures.

Smart Farm digitalizes fruit production activities through data-driven insights and automated monitoring capabilities, bringing real-time traceability.

Smart Doc streamlines documentation and regulatory compliance for seamless document management processes involved in the wine production supply chain.

Smart Lab presents a systematic organization of laboratory information management processes to furnish precise analytical and testing results during the quality control of fermentation and aging.

Smart Record utilizes the power of digital records to supervise and track all wine-making stages to ensure consistent wine quality.

Smart Specification can contribute to setting and monitoring specification requirements such as physical, chemical, microbial, nutritional, and allergens, for grape varieties and wine production.

Smart Compliance can help with the product release process by ascertaining adherence to the wine industry’s regulations and standards for product compliance in real-time.

Smart Integration facilitates the integration of various hardware devices such as sensors, enabling the cohesive execution of monitoring steps.

Smart Label is a labeling management software, using which customizable and accurate nutritional labels can be created to be put on wine bottles.

French

French

Spanish

Spanish

Portuguese

Portuguese