English

▾

English

▾

In the disciplined world of food manufacturing, excellence is measured not by grand gestures but by mastery of the mundane. Among the most underestimated yet critical hygiene controls is hair containment, a control so fundamental that lapses often go unnoticed until they trigger reputational and safety crises.

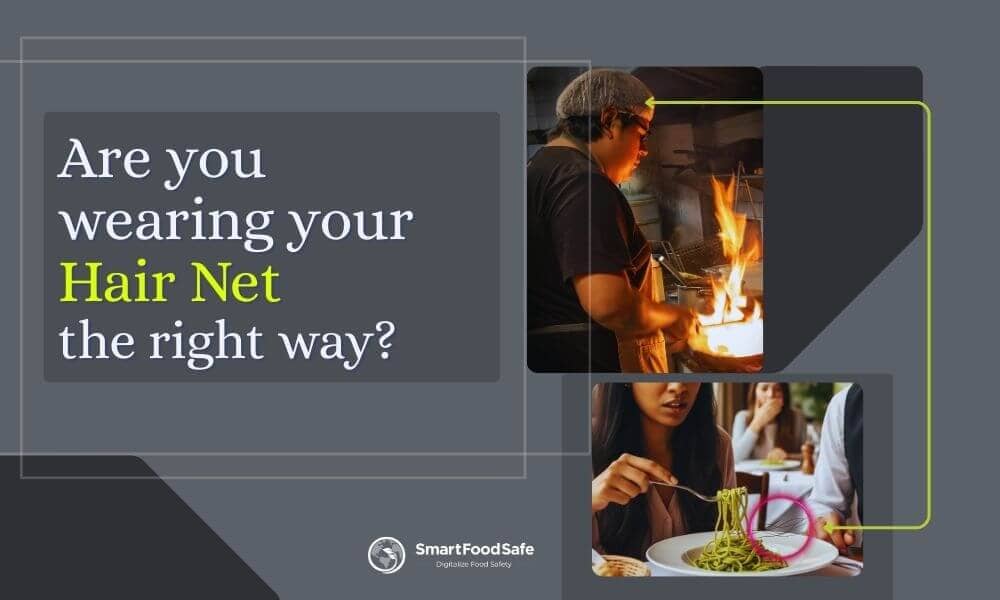

Hair is a recognised physical contaminant. National food codes and established hygiene frameworks require all food handlers with potential product contact to wear restraints that effectively prevent hair from entering food, food contact surfaces, or utensils and not merely to appear compliant.

If hairnets are mandatory, why do hair-related non-conformances keep showing up?

It’s a simple question, yet one that reveals a lot about behaviour, culture, and attention to detail in food manufacturing environments.

Understanding the Food Safety Risks of Hair Contamination

Human bodies shed hair constantly on average 33–50 strands per shift during routine activity. Unlike microscopic hazards, hair is visible, tangible, and instinctively rejected by consumers. More than an aesthetic complaint, a hair in a product is a marker of control failure and, in extreme cases, a biological vector that can carry bacteria, dandruff, and other contaminants.

This is why industry guidance stresses hair restraints such as:

- Hair nets and bouffant caps

- Chef hats and beard nets

- Proper procedures for donning before entering controlled areas

More than attire, they are primary contamination barriers that should be as standardised as handwashing or temperature control checkpoints. Because to the consumer, a single strand of hair can raise a damaging question: If this was missed, what else was?

The Consequences of Hair Contamination in Food Manufacturing

Hair contamination goes beyond a single rejected product. From a biological standpoint, hair can carry skin flora and microorganisms that may transfer to food or food contact surfaces, increasing the risk of contamination. For this reason, repeated hair containment failures are often viewed during audits as indicators of weak hygiene control and food safety culture.

For consumers, hair in food is an immediate trust breaker, signaling poor hygiene regardless of the actual risk involved. Operationally, these incidents lead to rework, waste, and investigations, diverting teams from improvement to damage control. Together, these impacts reinforce that hair containment is not just a visual standard but a critical food safety and business control.

How Human Behavior Affects Food Safety Culture

A policy is only as strong as its practice. Hair containment is a culture that lives in daily behaviour.

Contamination from workers can originate from the body itself, be it hair, skin debris, sweat, and even residues from personal care products, all capable of harming product integrity.

So what sustains real compliance?

1. Understanding the Why

Workers need to understand the importance of hair containment, not just the necessity of it. When workers grasp the biological and reputational implications, compliance becomes intentional, not perfunctory.

2. Shared Responsibility & Accountability

Food safety culture means peers monitor each other, supervisors model expected behaviours, and feedback channels exist without fear of reprisal. Such norms transform personal hygiene from a personal chore into a shared priority.

3. Training that Enlightens

Training should go beyond “wear a net” to:

- Demonstrating shedding statistics

- Explaining contamination vectors

- Showing audit repercussions

Food Safety Technology for Hair Contamination Prevention

In the digital age, technology has become a powerful reinforcement of human behaviour. It helps to reinforce good practices and reduce human error by making compliance visible, measurable, and accountable rather than aspirational.

Automated Cleaners & Vacuum Systems

Traditional sticky rollers are being augmented by automatic vacuum dust and hair cleaners that efficiently remove hairs from uniforms as workers enter controlled zones, without requiring manual effort. These systems can track usage and timing, enabling managers to monitor cleaning measures and intervene when necessary.

AI & Computer Vision Monitoring

Emerging food hygiene solutions are deploying AI-enabled cameras and computer vision systems to verify whether employees are wearing hair caps correctly and adhering to other hygiene standards as they move through production areas. Such systems can alert supervisors or trigger corrective actions automatically.

Data-Driven Hygiene Platforms

Digital HACCP and real-time monitoring platforms allow frontline workers to log hygiene checks instantly, and trigger alerts for non-compliance. This transforms subjective supervision into objective, measurable data, essential for audits and continuous improvement.

A Synergistic Approach of Culture and Technology

Hair containment may appear basic, but in food manufacturing, the strength of a safety system is revealed in how well the basics are upheld.

When organizations align:

- Clear, enforceable policies

- Human behaviour and culture change

- Technology that enhances visibility and consistency

you build a hygiene ecosystem that protects product integrity and preserves brand reputation.

Culture is the foundation of food safety, but technology is what sustains it under pressure.

The right systems make expectations visible, consistency achievable, and accountability fair. They don’t replace judgment; they support it. It is easier to repeat doing the right thing every shift, every day, when culture and technology collaborate.

French

French

Spanish

Spanish

Portuguese

Portuguese