English

▾

English

▾

A public health investigation into a 2022 Salmonella outbreak in Kazakhstan has recently concluded that the improper storage of cakes containing raw eggs was a key contributing factor. The incident, which unfolded during a wedding celebration, saw more than 60 attendees fall ill.

Salmonella Enteritidis, a known foodborne pathogen, was isolated from both the patient stool samples and the honey cakes. This outbreak, though localized, underscores a global issue: poor food storage and inadequate hygiene practices can have devastating consequences. By examining the root causes of such an incident and highlighting proactive solutions like digital environmental monitoring programs curated for them, food businesses can cut off such food safety mishaps from their origin.

Understanding What Really Happened: A Closer Look at the Causal Issues

The outbreak at the wedding was a textbook case of multiple failures converging to create the perfect storm:

1. Inadequate Storage Conditions

Honey cakes, a traditional delicacy with cream layers made from raw eggs, require refrigeration to inhibit bacterial growth. Due to insufficient refrigerator space in the kitchen, the cakes were stored at room temperature for extended periods. This provided ideal conditions for Salmonella proliferation.

2. Contaminated Ingredients and Surfaces

Environmental sampling identified Escherichia coli (E. coli) and Enterobacter spp. in various food items and preparation areas. The widespread contamination pointed to poor hygiene practices in the restaurant.

3. Non-Compliance to Sanitary Requirements

The restaurant lacked a valid sanitary certificate, and its staff did not possess health certificates, which are legally required to operate in Kazakhstan. This lapse highlights systemic issues in food safety enforcement.

4. Absence of Traceability

Key raw ingredients had been discarded, and no whole-genome sequencing was performed on the isolated bacteria. This limited the ability to trace the contamination’s source or establish a definitive link between the ingredients and the outbreak.

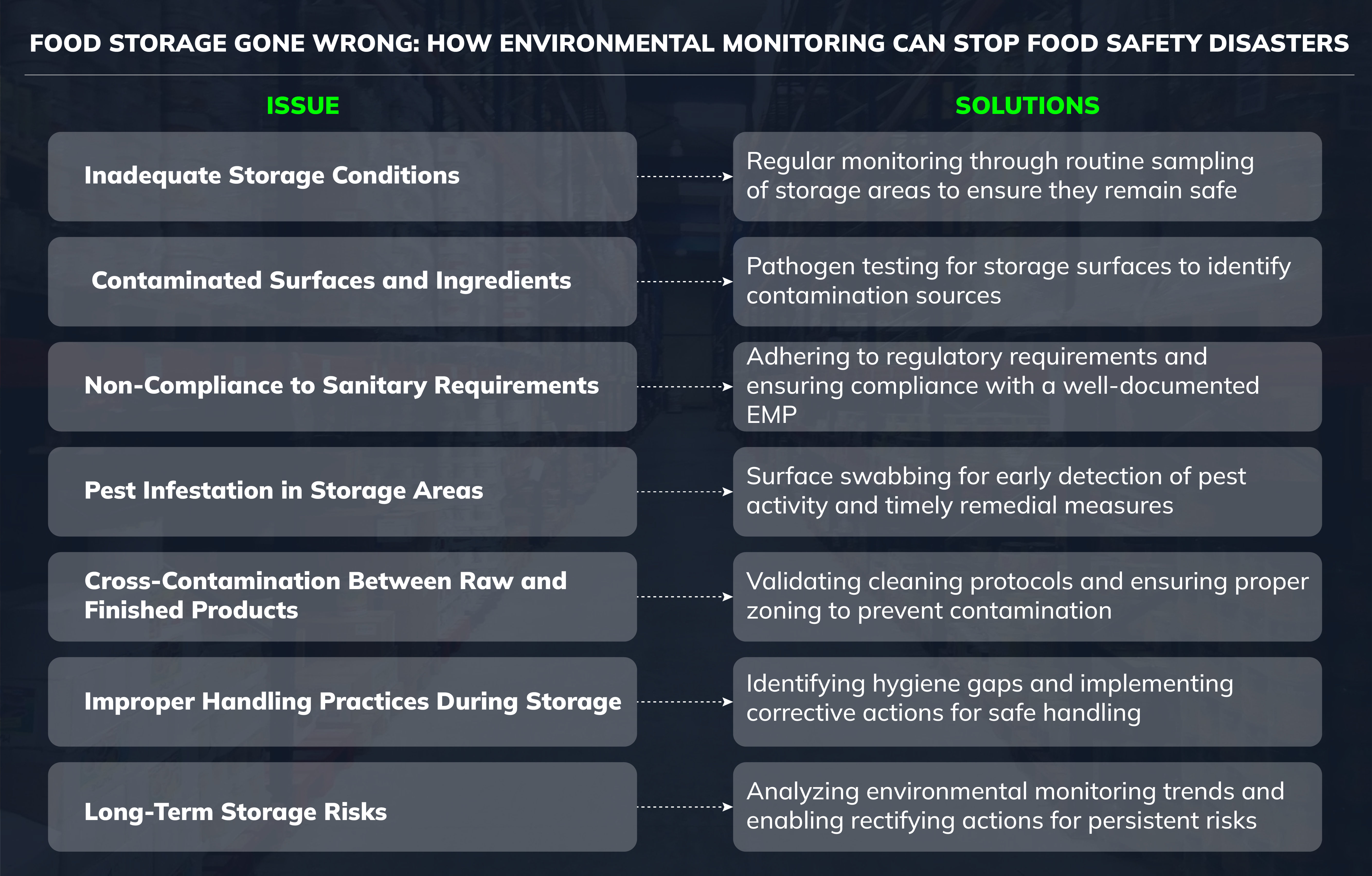

Rather than responding to incidents after they occur, food businesses must implement forward-thinking strategies that prevent contamination and outbreaks right from the starting point. Establishing an Environmental Monitoring Program (EMP) acts as a watchdog within food processing and storage environments. By thoroughly sampling and testing for pathogens, EMPs provide actionable insights that help mitigate risks. EMPs don’t just detect issues; they empower businesses to implement corrective actions and prevent future occurrences, creating a safer ecosystem for food production.

How an Effective EMP Can Make a Difference in This Scenario

An Environmental Monitoring Program (EMP) serves as a frontline defense against foodborne illnesses by ensuring that food production and storage environments remain free from harmful pathogens. In scenarios like the Kazakhstan honey cake outbreak, a well-implemented EMP could have drastically reduced the risk of contamination and the resulting health crisis. Here’s how:

• Monitoring Food Storage Environments for Pathogens

Proper storage is critical for maintaining food safety, and EMPs play a pivotal role in monitoring storage zones for contamination. Routine sampling of storage areas—such as refrigerators, freezers, and dry storage spaces—can help detect harmful microorganisms like Listeria monocytogenes and Salmonella. Early detection enables timely corrective actions, preventing the spread of contaminants that could compromise food safety and lead to product recalls or health crises.

• Controlling Temperature and Humidity Risks

Storage conditions, including temperature and humidity, are significant factors in preventing foodborne illnesses. EMPs incorporate environmental monitoring to ensure that storage conditions remain within safe parameters. For example, regular checks on refrigeration units can identify fluctuations or failures, reducing the risk of spoilage or pathogen growth in stored products.

• Identifying Gaps in Storage Hygiene

Contamination risks often stem from non-compliant hygiene practices in storage areas. EMPs systematically map contamination patterns to pinpoint hygiene lapses, such as unsanitized shelving, poorly cleaned containers, or pests in dry storage areas. Addressing these hygiene gaps promptly minimizes the chances of cross-contamination and ensures a safer storage environment.

• Validating Storage Cleaning Protocols

A comprehensive EMP also validates the effectiveness of cleaning and sanitation procedures specific to storage zones. For instance, swab tests on storage racks, bins, and packaging materials can confirm whether cleaning practices are sufficient to remove contaminants. Verification ensures that sanitization efforts effectively reduce risks in high-contact areas within storage facilities.

• Targeted Interventions for Storage Issues

EMPs enable businesses to implement targeted corrective actions when contamination is detected. For example, if testing identifies a localized issue, such as Listeria on a specific storage shelf, only the affected area requires immediate remediation rather than undertaking costly, facility-wide measures. This focused approach minimizes disruptions while effectively addressing the root cause.

• Compliance with Storage Regulatory Requirements

Food storage is subject to strict regulatory standards to prevent contamination risks. EMPs support compliance by documenting monitoring activities, corrective actions, and verification procedures. This documentation not only demonstrates adherence to food safety regulations but also builds trust with regulatory authorities and stakeholders.

• Preventing Long-Term Storage Risks

EMPs are dynamic tools that include trend analysis to identify recurring issues in storage environments. For example, analyzing data may reveal patterns such as consistent condensation in certain refrigeration units or insufficient air circulation in dry storage areas. Addressing these systemic issues enhances long-term food storage safety and efficiency.

While food storage risks are a mainstream focus for food safety, an EMP offers benefits beyond storage. Detecting and addressing contamination across all production and handling stages fosters food safety throughout the supply chain. From validating sanitation protocols to identifying gaps in hygiene practices, EMPs empower food businesses to mitigate any food safety risks with ease.

In conclusion, an EMP is not just about monitoring—it’s a proactive strategy that systematically reduces contamination risks in food manufacturing environments, ascertaining the integrity of food products, reinforcing food safety practices, and protecting consumer health.

Reimagine Environmental Monitoring Program With Smart EMP As Your First Line Defense Against Foodborne Outbreaks

Smart EMP bridges the gap between traditional practices and modern, proactive solutions to environmental monitoring, offering a transformative approach to food safety management. In scenarios like the Kazakhstan honey cake outbreak, where inadequate storage, poor hygiene, and lack of pathogen surveillance led to a public health crisis, Smart EMP becomes an indispensable tool.

Automating microbiological monitoring processes enables food businesses to identify contamination risks early, validate sanitation protocols, and maintain regulatory compliance easily. Tailored for operational efficiency, Smart EMP ensures your cleaning and hygiene efforts are data-driven, measurable, and impactful. Whether adapting existing environmental monitoring programs or building new ones, Smart EMP provides the agility and precision needed to mitigate risks, prevent outbreaks, and establish a culture of accountability in today’s complex food manufacturing environments.

French

French

Spanish

Spanish

Portuguese

Portuguese